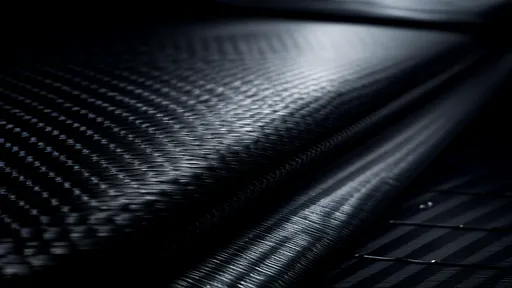

In the hushed laboratories of materials science, a quiet revolution has been unfolding—one that is reshaping the very fabric of modern industry. High-performance carbon fiber composites, often whispered about in engineering circles as the "Black Gold" of our era, represent not merely an advancement in materials technology but a fundamental shift in manufacturing philosophy. These materials, born from the marriage of carbon atoms woven into crystalline filaments thinner than human hair and embedded in polymer matrices, possess a paradoxical set of properties that once belonged solely to the realm of science fiction: the strength of steel at one-fifth the weight, the stiffness of titanium with superior fatigue resistance, and the corrosion resistance of platinum with unparalleled design flexibility. Their emergence signals a new chapter in human ingenuity, where the limitations of traditional materials are being systematically dismantled, one carbon strand at a time.

The journey of carbon fiber begins not with grandeur, but with the humble precursor of polyacrylonitrile or pitch-based fibers, subjected to a series of meticulously controlled thermal treatments. Through stabilization at moderate temperatures and carbonization in inert atmospheres reaching thousands of degrees Celsius, non-carbon atoms are relentlessly driven off, leaving behind a crystalline structure of pure carbon arranged in a mesmerizing graphitic pattern. This raw carbon fiber, though already impressive, undergoes one final transformation—surface treatment and sizing—to prepare it for its true destiny: integration into a composite matrix. It is here, in the symbiotic relationship between the carbon reinforcement and the polymer resin, that the material transcends its components, becoming something greater than the sum of its parts. The resulting composite is a masterpiece of molecular engineering, a material that can be tailored layer by layer, ply by ply, to meet the specific and often contradictory demands of the most challenging applications.

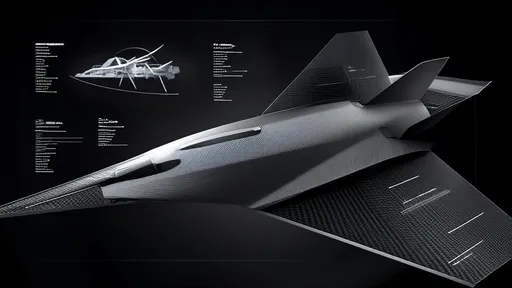

The aerospace and defense sectors were the earliest and most fervent adopters of this black gold, driven by an insatiable need for lightweighting without compromise. Every kilogram shed from an aircraft's structure translates directly into reduced fuel consumption, extended range, increased payload capacity, or a combination of these critical performance metrics. From the sleek fuselage and sweeping wings of the Boeing 787 Dreamliner and Airbus A350, where carbon composites constitute over 50% of the airframe by weight, to the stealth profiles of next-generation fighter jets whose radar-evading shapes are impossible to fabricate with metals, this material has become the bedrock of modern aviation. In the void of space, its virtues are even more pronounced; satellites and space probes, where every gram launched into orbit carries an astronomical cost, rely on carbon composites for their structural skeletons, antenna dishes, and instrument booms, leveraging their exceptional dimensional stability across the brutal temperature swings encountered beyond our atmosphere.

Yet, the allure of carbon fiber composites has long transcended the boundaries of aerospace, seeding a silent revolution in the world of terrestrial mobility. In the high-stakes arena of motorsports, from Formula 1 to endurance racing like Le Mans, the material is not a luxury but a fundamental tool for survival and victory. The monocoque chassis that forms the survival cell for a driver is a single, exquisitely molded piece of carbon composite, designed to absorb and dissipate immense crash energies while protecting its occupant. Beyond the track, the automotive industry is engaged in a delicate dance of adoption, balancing the phenomenal performance benefits against cost and mass-production challenges. Supercars from manufacturers like McLaren and Lamborghini have long been almost entirely fashioned from carbon fiber, but the true frontier lies in the mainstream. Here, the industry is pioneering the use of the material for critical components—roof panels, drive shafts, leaf springs—in luxury and performance sedans, achieving weight savings that improve handling, acceleration, and fuel efficiency, inching ever closer to the tipping point of widespread adoption.

The tendrils of this composite revolution are now extending deep into the infrastructure that underpins our civilization, promising to redefine resilience and longevity. In civil engineering, carbon fiber reinforced polymers are being deployed as external reinforcements for aging bridges, buildings, and parking garages. Wrapped like bandages around concrete pillars or bonded as laminates to weakened beams, these composites restore and often enhance the structural integrity of decades-old infrastructure, all without the need for bulky, disruptive steel plates. This application offers a faster, more durable, and often more economical path to extending the service life of critical assets. Furthermore, the material's corrosion resistance makes it ideal for harsh environments, from coastal structures battered by salt spray to chemical processing plants where metal components would rapidly succumb to decay. The wind energy sector, a cornerstone of the green transition, is also a voracious consumer. The quest for longer, more efficient turbine blades, capable of harvesting more energy from gentler winds, has found its answer in carbon fiber. Its high stiffness-to-weight ratio allows for the creation of blades that are both longer and lighter, reducing the loads on the turbine's hub and nacelle while pushing the boundaries of renewable energy generation.

Perhaps one of the most profound, yet less visible, impacts of high-performance carbon fiber composites is occurring in the realm of human potential and medical science. In the world of elite athletics, carbon fiber has enabled a new generation of equipment and prosthetics that blur the line between human and machine. The running blades used by Paralympic athletes are iconic examples—curved, lightweight carbon springs that store and return energy with an efficiency that can, in some cases, rival or even enhance biological limbs. This technology has not only redefined the limits of disabled sports but has also sparked complex conversations about human enhancement. Similarly, in competitive cycling, every frame, fork, and wheel set aspires to be lighter and stiffer, a pursuit made possible almost exclusively by advanced carbon layup techniques. Beyond sports medicine, carbon fiber's compatibility with medical imaging technologies like MRI and CT scans, due to its radiolucency, makes it an ideal material for surgical tables, patient positioning devices, and even external fixation devices, allowing for clearer imaging and more precise interventions without metallic artifacts.

Despite its illustrious title and transformative potential, the path of "Black Gold" is not without its significant shadows. The very processes that give carbon fiber its extraordinary properties are energy-intensive, relying on high-temperature furnaces that, if powered by conventional energy grids, carry a substantial carbon footprint. The industry is acutely aware of this paradox—a material that saves vast quantities of fuel in its application but consumes significant energy in its creation. In response, a concerted push is underway to develop more efficient production methods, utilize renewable energy sources for manufacturing, and explore bio-based precursors for the carbon fibers themselves. An even more daunting challenge lies at the end of the product's life cycle: recyclability. Thermoset composites, the most common matrix for high-performance applications, are notoriously difficult to recycle. Their cross-linked polymer chains do not melt upon reheating, making them resistant to traditional recycling processes. The global materials science community is therefore locked in a race to develop viable recycling technologies, from advanced pyrolysis that can recover the carbon fibers to the creation of new generations of thermoplastic composites that are more readily recyclable, ensuring that the legacy of this wonder material is not one of permanent waste.

As we stand at this materials crossroads, the future of high-performance carbon fiber composites shimmers with both promise and unanswered questions. Research frontiers are expanding into the nano-realm, with carbon nanotubes and graphene being integrated into composites to create multi-scale reinforced materials with properties we are only beginning to understand. The dream of "smart" or self-sensing composites is also nearing reality—structures with embedded carbon fiber networks that can monitor their own health, detecting internal damage like delamination or impact before it becomes critical. As additive manufacturing matures, the possibility of 3D printing complex, load-bearing structures from continuous carbon fiber filaments promises to unlock design freedoms that are impossible with conventional layup methods. The "Black Gold" of our age, therefore, is far more than a mere substitute for metal. It is an enabler of new forms, a catalyst for efficiency across vast sectors of the global economy, and a testament to our growing ability to engineer matter at the most fundamental level. Its story is still being written, one innovative application, one solved challenge, and one perfected strand at a time, as it continues to weave its way into the backbone of our technological civilization.

By /Oct 21, 2025

By /Oct 21, 2025

By Emily Johnson/Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By Natalie Campbell/Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By Noah Bell/Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025