The selection of high-performance carbon fiber composites as one of the 2025 Top Ten Global Engineering Achievements marks a watershed moment in materials science and industrial innovation. This recognition comes not merely as an academic accolade but as a testament to how this class of materials has fundamentally reshaped entire sectors, from aerospace to renewable energy, and set new paradigms for what is structurally and economically possible. The journey of carbon fiber composites, from specialized laboratory curiosities to mainstream engineering essentials, reflects decades of persistent research, refinement, and bold application.

The evolution of carbon fiber composites has been characterized by a relentless pursuit of performance and manufacturability. Early carbon fibers, while exceptionally strong and stiff for their weight, were prohibitively expensive and challenging to produce in complex shapes. The key breakthrough was not just in creating the fiber itself, but in developing the sophisticated matrix systems—typically epoxy resins—that bind the fibers together to form a composite. This synergy between fiber and matrix is what grants the material its remarkable properties: the fibers carry the load, while the matrix distributes stress, protects the fibers from environmental damage, and maintains the desired shape. Over the past two decades, advancements in precursor materials, pyrolysis processes, and automated manufacturing techniques like automated tape laying and resin transfer molding have driven down costs and scaled up production volumes, making these materials viable for a much broader range of applications.

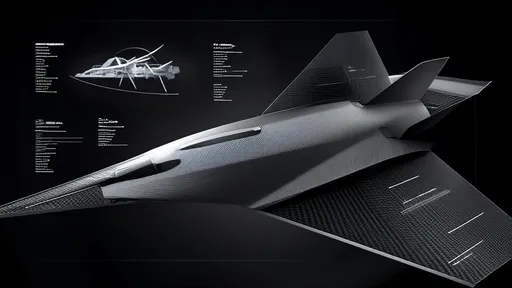

In the aerospace industry, the impact of carbon fiber composites has been nothing short of revolutionary. The development and success of aircraft like the Boeing 787 Dreamliner and the Airbus A350, both of which have airframes comprising over 50% composite materials by weight, served as a powerful proof-of-concept for the entire engineering world. The significant weight reduction compared to traditional aluminum alloys translates directly into massive fuel savings, lower emissions, and increased range or payload capacity. Beyond the fuselage and wings, composites are now ubiquitous in critical components such as engine fan blades, which must withstand immense centrifugal forces, and interior structures that enhance passenger safety and comfort. The material's resistance to corrosion and fatigue also drastically reduces maintenance requirements and extends the operational life of aircraft, creating a compelling economic case for their adoption.

The automotive sector is undergoing a similar, albeit more gradual, transformation driven by the dual pressures of electrification and lightweighting. For electric vehicles (EVs), every kilogram of weight saved extends the vehicle's range on a single battery charge—a critical factor in consumer adoption. High-performance carbon fiber is being strategically deployed in chassis components, body panels, and even in the battery enclosures themselves. While its use in mass-market vehicles was once limited to exotic supercars, innovations in fast-curing resins and high-volume production methods are bringing down the cost-per-part, making it increasingly common in premium sedans and SUVs. Furthermore, the high strength-to-weight ratio of composites allows for more creative and aerodynamic designs without compromising safety, as demonstrated by their use in impact-absorbing crash structures.

Perhaps one of the most impactful applications is in the field of renewable energy, particularly in the manufacture of wind turbine blades. As the quest for more efficient and powerful wind turbines continues, blades have grown longer to sweep a larger area and capture more energy. Constructing blades that are over 100 meters long from traditional materials like fiberglass presents immense challenges in terms of stiffness, weight, and resistance to fatigue. Carbon fiber composites have become the material of choice for the critical structural elements of these massive blades, particularly the main spar cap. Their superior stiffness and lower density allow for longer, lighter, and more durable blades that can operate reliably for decades in harsh environmental conditions, thereby lowering the levelized cost of wind energy and accelerating the global transition away from fossil fuels.

The penetration of carbon fiber composites into the sports and consumer goods industries has democratized high performance. What was once the exclusive domain of elite athletes is now accessible to enthusiasts worldwide. From tennis rackets and golf club shafts that offer a perfect blend of power and control to bicycles that are stiffer and lighter than ever before, these materials enhance the user experience by maximizing efficiency and responsiveness. In the realm of consumer electronics, carbon fiber is used to create lightweight yet rigid casings for high-end laptops and mobile devices, combining durability with a premium aesthetic. This widespread adoption in consumer markets has, in turn, fueled further investment in production scaling and cost reduction, creating a positive feedback loop that benefits more demanding industrial sectors.

Looking toward the horizon, the next frontier for high-performance carbon fiber composites lies in sustainability and advanced functionality. The engineering community is acutely aware of the environmental footprint associated with traditional carbon fiber production, which is energy-intensive and often relies on non-renewable precursor materials. Intensive research is now focused on developing bio-based precursors derived from sources like lignin or PAN, and on creating efficient recycling pathways to reclaim carbon fibers from end-of-life products. Beyond "green" production, the future is also about smart composites. Scientists are integrating nanomaterials like carbon nanotubes to create composites with embedded sensing capabilities, allowing a wind turbine blade or an aircraft wing to monitor its own structural health in real-time, detecting stress, strain, or damage before it becomes critical.

The selection of high-performance carbon fiber composites as a top global engineering achievement is a recognition of a material that has matured from a promising novelty into a foundational technology. It is a story of interdisciplinary collaboration between chemists, materials scientists, and mechanical engineers. Its success is measured not in laboratory specifications, but in the tangible benefits it delivers: more fuel-efficient aircraft, longer-range electric cars, more powerful renewable energy systems, and high-performance equipment that pushes the boundaries of human potential. As we advance, the continued innovation in this field promises not only to make existing applications better and more sustainable but also to unlock possibilities in medicine, construction, and deep-sea exploration that we are only beginning to imagine.

By /Oct 21, 2025

By /Oct 21, 2025

By Emily Johnson/Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By Natalie Campbell/Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By Noah Bell/Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025