In the quiet hum of a Tokyo electronics factory, a pair of synthetic hands performs a delicate ballet, assembling circuitry with a precision that surpasses human capability. Across the globe, in a Stockholm retirement home, another humanoid form gently assists an elderly resident from their bed. These are not scenes from science fiction but snapshots of a present-day reality where humanoid robots are transitioning from laboratory prototypes to active participants in our industrial and social landscapes.

The journey of humanoid robotics has been one of fits and starts, punctuated by periods of intense hype and subsequent disillusionment. For decades, the field promised much but delivered little beyond carefully choreographed demonstrations. What has changed in recent years is not merely incremental improvement but a convergence of technologies that has finally enabled these machines to navigate the unpredictable chaos of human environments. The once-distant dream of robots working alongside us is materializing with tangible applications that signal a profound shift in how we approach labor, care, and daily life.

Industrial Evolution: Beyond the Assembly Line

Traditional industrial robots have long been confined to safety cages, performing repetitive tasks in highly structured environments. The emergence of humanoid robots represents a fundamental departure from this paradigm. Companies like Boston Dynamics with their Atlas robot and Tesla with their Optimus prototype are developing machines capable of integrating directly into existing workplaces without massive infrastructure changes.

The advantage of the human form factor becomes immediately apparent when considering the billions of dollars invested in creating environments designed for human proportions. Factories, warehouses, and construction sites are built around staircases, doorways, and tools sized for people. Humanoid robots can step into these spaces and utilize the same equipment, vehicles, and facilities without costly retrofitting. This compatibility offers a practical pathway to automation that doesn't require rebuilding the physical world from scratch.

At the BMW manufacturing plant in Spartanburg, South Carolina, humanoid robots are being tested for logistics tasks that fall between the capabilities of traditional automation and human workers. These robots can navigate between assembly stations, retrieve components, and perform quality checks in spaces too confined for larger automated systems. The implementation demonstrates a key insight: humanoids aren't necessarily replacing existing automation but filling the gaps where conventional robots struggle.

What makes these industrial applications particularly compelling is their learning capability. Unlike programmed industrial arms that execute identical movements thousands of times, humanoid robots increasingly employ artificial intelligence that allows them to adapt to variations in their environment. When a part is slightly out of position or a tool isn't exactly where expected, these robots can adjust their approach rather than halting operations and requiring human intervention.

The Social Dimension: Robots in Human Spaces

Perhaps more revolutionary than industrial applications is the gradual introduction of humanoid robots into social and service contexts. While industrial robots interact primarily with objects, social robots must navigate the far more complex realm of human interaction, with all its nuances, unpredictability, and emotional dimensions.

In healthcare settings, robots like Japan's ROBEAR are demonstrating remarkable potential. Designed specifically for lifting patients, ROBEAR combines the strength to safely move individuals with sensors and programming that ensure gentle, careful handling. This application addresses both practical needs—reducing physical strain on healthcare workers—and emotional ones, as the robot can perform repetitive lifting tasks consistently without fatigue or frustration.

Education represents another frontier where humanoid robots are making inroads. Research from Stanford University has shown that children with autism spectrum disorders often engage more readily with robot tutors than human instructors. The predictable, non-judgmental nature of robot interaction creates a safe learning environment where children can practice social skills without anxiety. Similarly, language learning applications have demonstrated that students feel less self-conscious making pronunciation mistakes with robot tutors than with human teachers.

The retail and hospitality industries are experimenting with humanoid robots as well. At Japan's Henn na Hotel, humanoid robots handle front desk operations, while in some Singaporean restaurants, robot servers deliver meals to tables. These implementations are as much about operational efficiency as they are about customer experience—the novelty of robot interaction itself becomes part of the service offering.

Technical Breakthroughs Driving Adoption

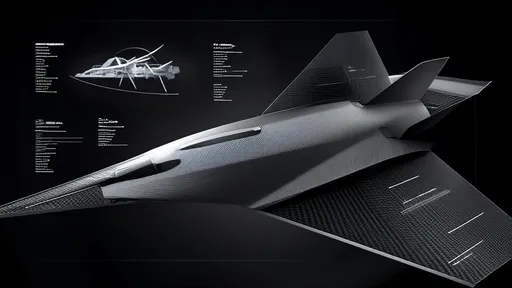

Several critical technological advances have converged to make current-generation humanoid robots viable where their predecessors failed. Motion control and balance algorithms have improved dramatically, enabling bipedal robots to navigate uneven surfaces and recover from disturbances that would have sent earlier models tumbling. The development of hydraulic actuators that mimic human muscle responsiveness has been particularly important for creating fluid, natural movement.

Computer vision represents another leap forward. Modern humanoid robots employ sophisticated sensor suites that combine LIDAR, stereo cameras, and depth sensors to create rich 3D maps of their surroundings in real time. This environmental awareness allows them to identify objects, avoid obstacles, and understand spatial relationships—capabilities essential for operating in dynamic human environments.

Perhaps the most significant advancement has been in the artificial intelligence that controls these machines. Early humanoid robots operated primarily through pre-programmed motions, while contemporary systems increasingly use machine learning to develop skills through practice and simulation. Tesla's approach to training their Optimus robot through neural networks and simulation represents a fundamental shift from programming behaviors to cultivating capabilities.

Battery technology and power management have also seen crucial improvements. The energy requirements for bipedal locomotion are substantial, and early humanoid robots suffered from limited operational time between charges. New battery chemistries and more efficient motor designs have extended operational periods to practical durations, with some current models able to work for several hours before requiring recharge.

Economic and Social Implications

The expanding capabilities of humanoid robots raise important questions about their economic impact. While fears of widespread job displacement dominate popular discourse, the reality appears more nuanced. In manufacturing, humanoid robots are increasingly being deployed not as replacements for human workers but as complements—handling tasks that are physically demanding, dangerous, or ergonomically challenging.

Demographic trends in many developed nations create a compelling case for robotic assistance. With aging populations and shrinking workforces in countries like Japan, Germany, and South Korea, humanoid robots may help maintain economic productivity and care infrastructure that would otherwise strain under demographic pressure. Rather than replacing workers, they may fill positions that would otherwise go unfilled.

The economic model for humanoid robotics is also evolving. While early research and development required massive investment, costs are declining as components become commoditized and manufacturing processes improve. Companies like Unitree Robotics have demonstrated that capable bipedal robots can be produced at increasingly accessible price points, suggesting that broader adoption across industries may be economically feasible sooner than previously anticipated.

Social acceptance remains a critical factor that will influence adoption rates. Cultural attitudes toward robots vary significantly—while Japanese society has generally embraced robotic assistance, other cultures exhibit more skepticism. Transparency about capabilities and limitations, along with clear demonstrations of benefit, will be essential for building public trust.

Ethical Considerations and Future Directions

As humanoid robots become more capable and widespread, they raise complex ethical questions that society must address. The creation of machines that mimic human appearance and behavior challenges our understanding of interaction and relationship. When robots care for the elderly or educate children, what responsibilities do manufacturers and operators bear for the psychological impact of these relationships?

Privacy concerns emerge naturally from robots equipped with extensive sensor arrays operating in homes and workplaces. The data collected about human behavior patterns, physical spaces, and daily routines represents a significant privacy consideration that requires thoughtful regulation and transparent handling.

Looking forward, the trajectory of humanoid robotics points toward increasing specialization. While general-purpose humanoid robots capture imagination, near-term commercial success may come from machines designed for specific domains—healthcare assistants, educational companions, or logistics specialists. This specialization allows for optimization around particular use cases while managing complexity.

Research institutions and companies are already looking beyond current capabilities. The next frontier involves robots that can not only perform physical tasks but understand and respond to human emotional states. Affective computing—technology that can recognize and respond to human emotions—could enable a new generation of robots capable of more nuanced social interaction.

The development of humanoid robotics represents one of the most ambitious technological undertakings of our era—an attempt to recreate, in synthetic form, the capabilities that evolution spent millions of years refining. The applications emerging in industrial and social contexts suggest we are approaching an inflection point where these machines transition from fascinating experiments to practical tools that augment human capability and address societal challenges.

What makes the current moment particularly significant is that after decades of speculation and false starts, humanoid robots are finally demonstrating real-world utility. They are moving components in factories, assisting caregivers in hospitals, and helping educators in classrooms. The promise is no longer theoretical but demonstrated in functioning applications that point toward a future where humans and humanoid robots collaborate in shared spaces, each bringing their unique strengths to complementary roles.

By /Oct 21, 2025

By /Oct 21, 2025

By Emily Johnson/Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By Natalie Campbell/Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By Noah Bell/Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025