The relentless pursuit of miniaturization and performance in the semiconductor industry has entered a new, three-dimensional phase. For decades, the guiding principle was Moore's Law, the observation that the number of transistors on a microchip doubles about every two years, achieved primarily by shrinking transistor sizes on a flat, two-dimensional plane of silicon. However, as we approach the physical and economic limits of this scaling, the industry's focus has dramatically shifted upwards. The new frontier is not just making things smaller, but stacking them. 3D chip stacking and advanced packaging technologies have moved from niche applications to the central strategy for continuing the pace of innovation, promising to redefine the very architecture of computing for the AI era and beyond.

The concept of stacking chips is not entirely new, but its implementation has evolved from simple memory dies in a single package to highly complex, heterogeneous systems. The fundamental driver is the growing inefficiency of the traditional monolithic system-on-chip (SoC). As these chips have grown larger to accommodate more functions, the physical distance that signals must travel between different components, like the CPU cores and memory, has increased. This distance, known as the interconnect delay, becomes a significant bottleneck for speed and power consumption. By stacking chips vertically and connecting them with thousands of ultra-short, vertical interconnects, this delay is slashed. Data can move between functional blocks at unprecedented speeds and with far less energy, a critical advantage for data-intensive applications like artificial intelligence, high-performance computing, and 5G networking.

At the heart of this 3D revolution are several key enabling technologies. Through-Silicon Vias (TSVs) are the microscopic vertical conduits that electrically connect a stack of dies. Creating these involves etching deep, narrow holes through the silicon wafer, lining them with an insulating layer, and filling them with a conductive material like copper. The development of high-aspect-ratio TSVs—incredibly deep yet narrow—has been a monumental engineering achievement, allowing for a massive density of connections without compromising the structural integrity of the silicon. Alongside TSVs, hybrid bonding has emerged as a game-changer. Unlike older techniques that used solder bumps to connect dies, hybrid bonding directly fuses the copper interconnects on the surface of two dies with a dielectric material, creating a permanent, atomic-level bond. This process enables an order-of-magnitude increase in connection density and allows for finer pitches, meaning more connections in a smaller area, which is essential for achieving the bandwidth demands of tomorrow's chips.

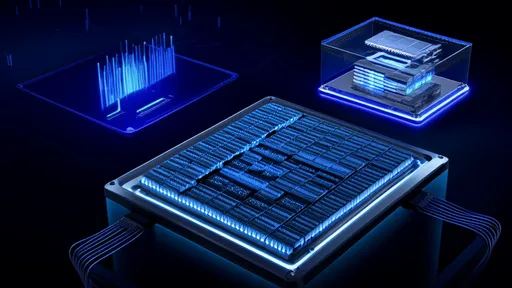

The industry is no longer just stacking identical memory chips. The most powerful trend is heterogeneous integration, where fundamentally different types of chips, often manufactured on different process nodes optimized for their specific function, are integrated into a single package. Imagine a system where a high-performance logic chip built on the latest 3nm process is stacked atop a specialized analog/RF chip made on a older, more cost-effective 28nm node, with a high-bandwidth memory (HBM) cube sitting right beside them, all connected through a sophisticated silicon interposer. This "mix-and-match" approach allows designers to break free from the constraints of a one-size-fits-all manufacturing process. They can optimize each component for performance, power, and cost, and then integrate them into a system that performs as if it were a single chip. This is the architectural shift enabling the specialized accelerators that power modern AI and machine learning workloads.

The role of the package itself has been utterly transformed. It is no longer a simple protective shell with pins to connect to a circuit board; it has become an active platform for integration—a system-in-package (SiP). Silicon interposers, passive slices of silicon embedded with a dense network of wiring, act as a miniature motherboard within the package, routing signals between chiplets with high efficiency. Even more advanced are embedded silicon bridge technologies, where small pieces of silicon with ultra-dense interconnect routes are embedded within the package substrate to connect chiplets over very short distances. On the horizon, glass substrates are being researched as a successor to organic substrates and silicon interposers. Glass offers superior flatness, thermal and mechanical stability, and the potential for even finer wiring, which could support an even greater number of connections for future 3D architectures.

The implications of these advancements are profound and are already being felt across the technology landscape. In artificial intelligence, the ability to place vast pools of high-bandwidth memory immediately adjacent to AI accelerator cores is eliminating the memory bottleneck that has constrained model size and training times. This co-packaged architecture is what allows for the trillion-parameter models that are pushing the boundaries of what AI can do. In data centers, CPUs are increasingly being designed as collections of smaller "chiplets" rather than a single large die. These chiplets, which might include compute cores, I/O interfaces, and cache memory, can be tested separately and then integrated using advanced packaging, improving manufacturing yield and allowing for more modular and scalable server designs. For consumer devices, these technologies enable the sleek, powerful gadgets we use daily, allowing for more functionality to be packed into a smaller form factor without sacrificing battery life.

Despite the tremendous progress, significant challenges remain on the path to ubiquitous 3D integration. Thermal management is perhaps the most daunting. Stacking power-hungry chips creates a high power density, turning these packages into miniature ovens. Dissipating this heat effectively to prevent performance throttling or damage requires innovative cooling solutions, from advanced thermal interface materials and heat spreaders to integrated microfluidic channels that pump coolant directly through the stack. Testing and yield present another complex puzzle. Testing a fully assembled 3D stack is exceedingly difficult if an underlying die is found to be faulty. Strategies like known-good-die (KGD) testing, where each die is rigorously tested before assembly, and built-in self-test (BIST) circuits are critical but add cost and complexity. Furthermore, the design tools and electronic design automation (EDA) software needed to architect these complex 3D systems are still maturing, requiring a new generation of tools that can handle the multi-physics challenges of thermal, mechanical, and electrical co-design.

Looking forward, the trajectory of 3D integration points toward even greater intimacy between components. We are moving from 3D packaging, where fully fabricated chips are stacked, to true 3D monolithic integration, where transistor layers are built directly on top of each other on a single wafer. This nascent technology, often called sequential integration, could eventually lead to systems with logic transistors stacked over memory cells, creating an unparalleled level of performance and efficiency. The industry is also exploring the integration of non-silicon elements, such as photonics, for light-speed data movement within the package, and the inclusion of sensors and micro-electromechanical systems (MEMS) to create complete sensing and computing systems on a chip. The package is becoming the new motherboard, the new server rack, and the new city planner for the world of computing, orchestrating the flow of data in three dimensions.

In conclusion, the era of simply scaling down transistors on a flat plane is giving way to a more sophisticated, multi-dimensional approach. 3D chip stacking and advanced packaging are not merely incremental improvements; they represent a fundamental paradigm shift in semiconductor design and manufacturing. By building up rather than just scaling down, the industry is overcoming the limitations of Moore's Law and paving the way for a new generation of powerful, efficient, and highly specialized computing systems. This vertical revolution is building the foundation for the next decade of technological innovation, from pervasive AI and the metaverse to discoveries in genomics and materials science that we have yet to imagine.

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025